8

12

4.5

380

Own production center

We adapt to customer needs

Wind tunnel test

Patent pending

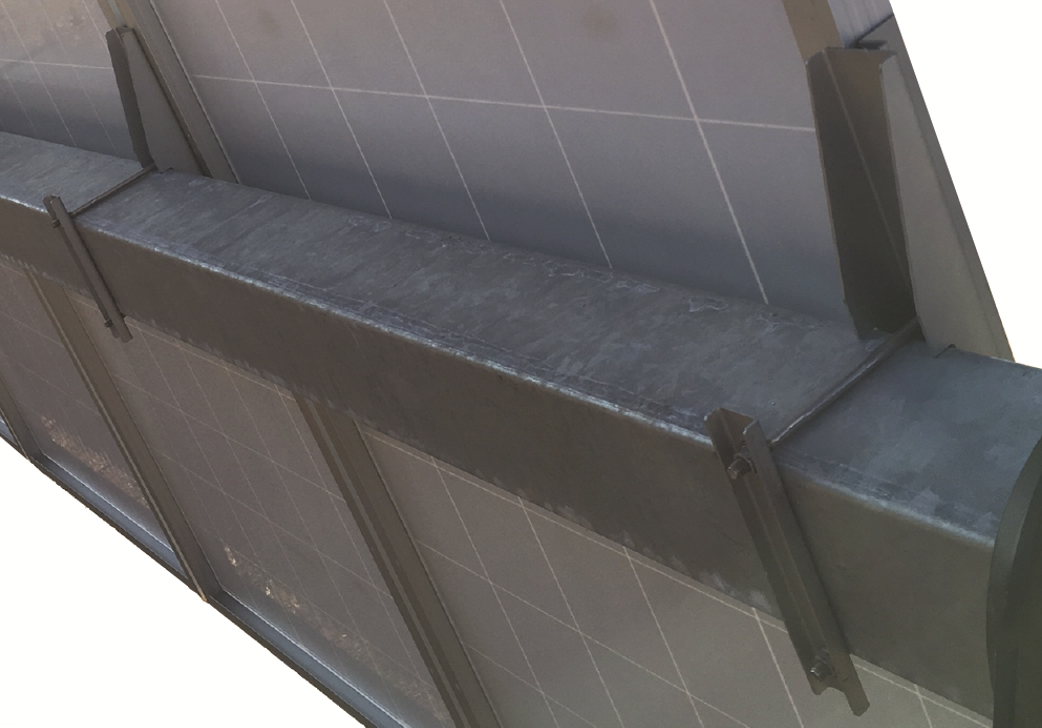

Nclave has developed and patented an innovative module mounting design that reduces both material and installation costs for framed modules.

Main characteristics:

Benefit: